Laser markingand cut

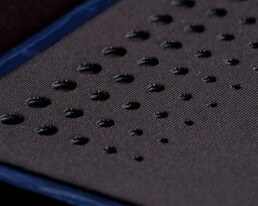

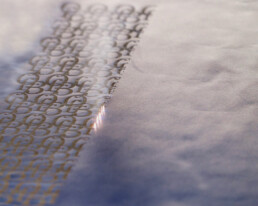

In the production of fashion accessories, Officina 3 relies on laser cutting and marking for the finishing of the products made, through marked decorations, perforations and precision cuts. Thanks to the use of these technologies, we complete all the creative aspects of fashion accessories, according to the requests of our customers.

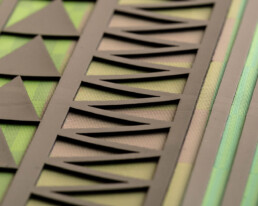

Laser cutting in the fashion sector uses the energy of lasers to quickly cut synthetic materials, technical fabrics such as polyester, lycra, fleece, or fine fabrics such as lace, silk, linen, leather, alcantara, leather, nubuck, suede and denim. Reproducing customized shapes of particular complexity or simply making rounded cuts requires the particular precision and speed of this technique.

On the other hand, laser marking on leather is used to remove very thin layers of material, creating hollowing and three-dimensional effects. In a few seconds the initial surface of the skin is transformed into a marked surface with a well-defined and permanent bas-relief effect. The laser marking is resistant to treatments and washing.

The advantages of using laser technology in the fashion industry are numerous: cutting and marking are done quickly and repeatedly and are ideal for mass production. The edges obtained are clean, have no burrs and are perfectly welded. They are flexible and versatile techniques that are applied to all materials and allow the creation of highly complex designs

Contact us to find out more

Are you interested in our products? Do you want to request a quotation? Are you a company or a private and want to collaborate with us? Fill out the form and let us know!

"*" indicates required fields